The cold weather test of a Tesla Model 3 has provided valuable insights into how the electric vehicle handles extreme temperatures. The facelifted Model 3 was left outside in the freezing Canadian winter, and the owner didn't precondition the interior or the battery. This unusual experiment aimed to assess the car's performance under harsh conditions.

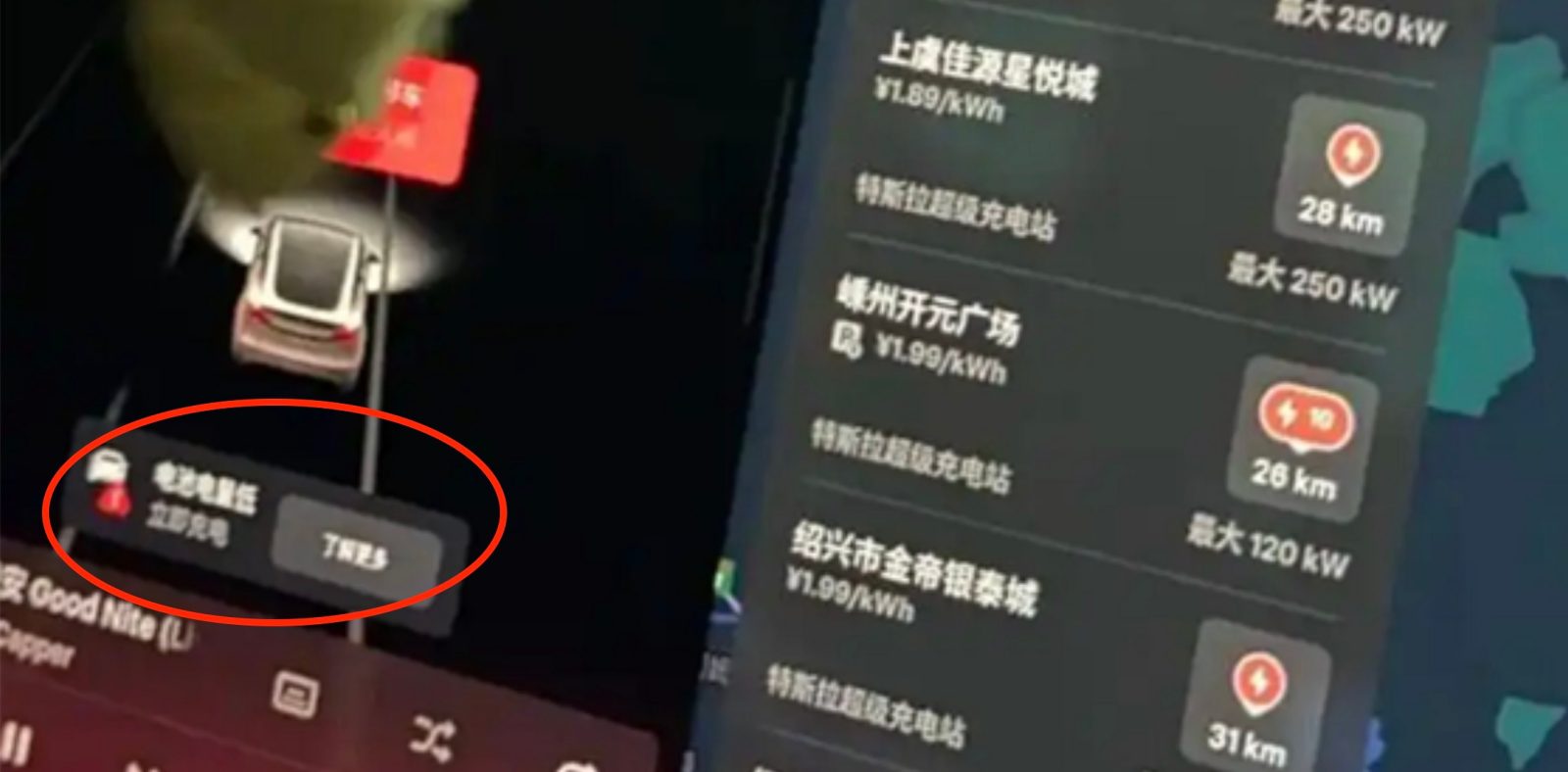

As a result, the car's charging efficiency took a significant hit due to the prolonged exposure to subzero temperatures. The extreme cold also affected the vehicle's comfort features, making it an uncomfortable place to be inside. Despite its electric powertrain, the Model 3 still relies on various components that can be compromised by freezing temperatures.

These include the battery management system and the charging infrastructure. The test highlights the importance of proper maintenance and precautions when driving in extremely cold conditions. For instance, preconditioning the interior and battery before leaving the car unattended is crucial to prevent damage.

The experiment also underscores the need for vehicle owners to be aware of their car's limitations in such conditions. In this context, it's essential to understand how different components interact with extreme temperatures. The results of this test will likely inform Tesla's strategies for improving its vehicles' performance and efficiency in cold climates.

As a result, drivers can expect future models to be better equipped to handle such conditions. The experiment also raises questions about the long-term durability of electric vehicles in extreme environments. Will electric cars be able to withstand the harsh conditions that traditional gas-powered vehicles can?

Only time will tell. In any case, this unusual test has provided valuable insights into the performance and efficiency of the Tesla Model 3 in freezing temperatures.

This experiment serves as a reminder for drivers to take necessary precautions when driving their electric vehicles in extreme cold weather conditions. By understanding how different components interact with subzero temperatures, manufacturers can develop more efficient and reliable systems that minimize downtime and optimize performance.