Daily news

News

Daily updates from transport, logistics, equipment, and mobility.

Heavy Equipment

Back to homeCategory:Heavy EquipmentTap to change

Heavy Equipment Guide (All news)·Heavy Equipment·Feb 3, 2026

Blue Diamond Attachments' New Website Streamlines Parts and Accessories Purchasing

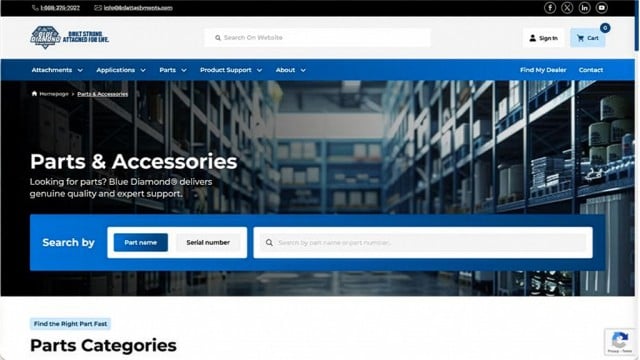

Blue Diamond Attachments has launched a new parts and accessories website, BDAParts.com, to provide visitors with greater functionality and an improved user experience. The company's goal was to simplify parts and accessories searches for its product categories, ranging from blades to brush cutters, buckets, grapples, and more. The site also includes a large number of universal parts and accessories for attachments from other OEMs. With the new website, visitors can now easily search for parts and accessories by part name or serial number. The ecommerce function allows customers to select parts and accessories, review their pending purchase, including taxes and shipping, and securely complete their checkout. This overhaul was made with the customer's experience at the forefront of its development, according to Darren Barnes, director of products at Blue Diamond Attachments. By streamlining the purchasing process, BDAParts.com aims to make it easier for visitors to find what they need, while also offering convenience through an ecommerce function. The new website is a significant improvement over the company's previous parts and accessories site, providing a more user-friendly experience for customers. With its launch, Blue Diamond Attachments is confident that it has created a better platform for its customers to purchase parts and accessories.

Heavy Equipment Guide (All news)·Heavy Equipment·Feb 3, 2026

MAGNI's Four New Teleshandler Models Feature Smart Tech Solutions

MAGNI Telescopic Handlers has expanded its range of telescopic handlers with the introduction of four new models, designed to deliver reliable lifting performance, operational flexibility, and an optimized investment for everyday on-site work. The new TH 9.50 and TH 9.62 offer a maximum lifting capacity of 8,800 pounds and working heights of 50 and 62 feet respectively, meeting the needs of construction, industrial, and logistics applications. These models are part of the TH range, which includes basic and functional configurations focused on lifting performance. The main difference between the two versions lies in the engine, with the inclusion of the letter 'P' in the MAGNI TH model name taking on a new meaning of performance, reserved for engines with power outputs greater than 75 kW. With the introduction of these models, MAGNI TH has strengthened its offering with the introduction of the 8,800 lbs range: versatile, high-performance machines designed to ensure efficiency, reliability, and productivity in the most common lifting applications. The new designs prioritize operational reliability and optimized investment costs without compromising on performance. This strategic move positions MAGNI as a leader in the telescopic handler market, catering to the diverse needs of various industries. By incorporating smart tech solutions, these new models aim to enhance the overall user experience and provide long-term benefits for customers. With their advanced features and reliable performance, the new TH 9.50 and TH 9.62 are poised to become a valuable asset in construction, industrial, and logistics projects. The inclusion of these models marks an exciting development in MAGNI's product line, solidifying its position as a trusted partner for on-site work requirements. These machines are designed to meet the evolving needs of industries, providing solutions that balance performance, reliability, and cost-effectiveness.

Heavy Equipment Guide (All news)·Heavy Equipment·Feb 2, 2026

Darda's Demolition Attachments for Compact Carriers Now Available in North America

Darda North America has expanded its product offerings by bringing the power and performance of their attachments for compact carriers to the U.S. and Canada. The company's lineup includes a range of bolt cutters, concrete crushers, rock splitters, shears, and tank cutters designed for various applications such as interior demolition, trenching, and rock excavation. These attachments offer high-performance solutions with low-noise, low-dust, and low-vibration characteristics, making them ideal for controlled and efficient operations. With their robust design and versatility, Darda's compact carrier attachments are poised to revolutionize the construction and demolition industries in North America. By providing a range of attachment options, Darda North America is catering to the diverse needs of its customers, from small-scale projects to large-scale infrastructure developments. The company's commitment to innovation and customer satisfaction has enabled it to establish itself as a leading provider of attachments for compact carriers in the region. As the demand for efficient and cost-effective demolition solutions continues to grow, Darda North America is well-positioned to meet this need with its comprehensive range of attachments. The company's products are designed to provide safe, reliable, and high-performance operations, reducing downtime and increasing productivity. With its extensive product lineup and commitment to customer satisfaction, Darda North America is set to become a major player in the compact carrier attachment market in North America. By expanding its presence in the region, Darda North America aims to build strong relationships with its customers and provide them with the best possible solutions for their demolition needs. The company's expansion into North America marks an exciting new chapter in its history, as it looks to establish itself as a leading provider of attachments for compact carriers in the region. With its robust product lineup and commitment to innovation, Darda North America is poised to make a significant impact on the construction and demolition industries in North America.

Heavy Equipment Guide (All news)·Heavy Equipment·Feb 2, 2026

BOMAG's New BP Series Vibratory Plate Compactors Feature Customizable Design

BOMAG has introduced its new BP Series of single direction vibratory plate compactors, designed to deliver high compaction results across a range of applications. The new line features six gas engine models with varying compaction widths and includes several innovative features such as cyclone filters, bar guards, and vibration system designs. These compactors are designed for minimal exhaustion on long jobs and can be customized with various accessories like transport wheels and polyurethane mats to suit different applications. With their rugged design and durable build, the BP Series is ideal for contractors working in soil, paver block, asphalt construction, and paving. The new line offers a range of options for compaction widths from 12.6 inches to 19.7 inches, making it suitable for various projects. Additionally, the compactors' ergonomic design features directly accessible service points to minimize downtime. BOMAG's BP Series is designed to provide efficient and effective compaction results while minimizing operator fatigue. The new line also includes a range of accessories that can be easily installed or removed as needed, such as transport handles, guide handles, and polyurethane mats. With their compact dimensions and foldable guide handle, the compactors are easy to maneuver and store when not in use. The BP Series is available with six gas engine models, offering contractors a range of options for different applications. The new line also includes several safety features such as bar guards and vibration system designs that minimize the risk of damage or injury. Overall, BOMAG's new BP Series vibratory plate compactors are designed to provide efficient and effective compaction results while minimizing operator fatigue and downtime.

Heavy Equipment Guide (All news)·Heavy Equipment·Feb 2, 2026

RPC Invests in Topcon Solutions Stores to Accelerate Construction Technology Adoption

Topcon Positioning Systems has received a strategic investment from RPC, Inc. in its U.S. retail network — Topcon Solutions Stores (TSS) — marking a major milestone for the Topcon organization and its impact on the construction technology market in the U.S. The investment will strengthen TSS's commitment to help more contractors modernize their job sites through innovative technology solutions. Long-term structural trends in the U.S. construction market, including housing shortages, infrastructure investment, and modernization of aging assets, continue to drive demand for tech-enabled retailers to lead the next phase of industry transformation. RPC, Inc. sees this moment as an opportunity to support Topcon Solutions Stores in their journey to drive technology adoption. The company's CEO David Alban stated that he believes tremendous opportunity exists in the U.S. construction sector, particularly as contractors accelerate their projects through digital transformation. Ivan Di Federico, president and CEO of Topcon Positioning Systems, noted that RPC, Inc.'s investment reflects the growing recognition that positioning technology and job site automation are essential to the future of construction. Murray Lodge, executive vice president of construction for Topcon, emphasized that the construction industry is changing rapidly and this investment strengthens the push toward improved productivity and performance. Mark Contino, vice president of Topcon North American retail distribution, TSS, highlighted that the benefits offered by TSS will continue to accelerate with the growth potential brought by this investment.

Heavy Equipment Guide (All news)·Heavy Equipment·Feb 2, 2026

Hillhead Show Prepares for 2026 Event

The Hillhead Show, a leading international exhibition for the construction, quarrying, and recycling industries, is gearing up for its 2026 event with significant expansions to visitor infrastructure. The show, which takes place at the NEC in Birmingham, UK, will feature a range of new attractions and facilities designed to enhance the visitor experience. The expanded layout will provide more space for exhibitors and visitors alike, allowing for a more immersive and engaging experience. This year's show is expected to attract thousands of visitors from across the globe, showcasing the latest innovations and technologies in the construction, quarrying, and recycling sectors. The Hillhead Show has been a staple of the industry calendar for over 100 years, providing a unique platform for companies to connect with customers, showcase their products, and stay ahead of the curve. With its rich history and reputation for excellence, the show is an essential event for anyone involved in the construction, quarrying, and recycling industries. The expanded visitor infrastructure will include new public areas, improved accessibility, and enhanced amenities, all designed to make the show more enjoyable and productive for visitors. The NEC's facilities have been upgraded to accommodate the increased demand, with additional parking, improved catering options, and enhanced security measures in place. The Hillhead Show is a must-visit event for anyone looking to stay up-to-date with the latest developments in the construction, quarrying, and recycling sectors. With its expanded visitor infrastructure, the show is set to be bigger and better than ever. The organizers are confident that the 2026 event will exceed expectations and provide an unforgettable experience for all attendees. As we look ahead to the 2026 event, it's clear that Hillhead Show is committed to delivering a world-class experience that meets the evolving needs of its visitors. With its rich history, reputation for excellence, and commitment to innovation, Hillhead Show is an event not to be missed.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 30, 2026

John Deere to Open Excavator Manufacturing Facility in North Carolina

John Deere is set to open a new $70 million excavator manufacturing facility in Kernersville, North Carolina, further solidifying its commitment to supporting local economies and strengthening the backbone of American industry. The company has also announced plans for two other U.S.-based facilities: a distribution centre near Hebron, Indiana, and another factory in Kernesville, North Carolina. These investments are expected to generate significant employment opportunities nationwide. With these new facilities, John Deere aims to enhance supply chain capabilities, streamline operations, and ensure timely delivery of equipment and parts to its customers. The company's dedication to supporting local economies is evident in its investment in these new facilities. By leveraging advanced technologies, the North Carolina factory will bolster John Deere's manufacturing capabilities, producing excavators for the construction market. The project is anticipated to be a significant boost to the region's thriving manufacturing community. With this investment, John Deere aims to deliver excellence and create jobs, advancing its legacy of manufacturing excellence. The company's focus on customer expectations around world-class product support will also be a key aspect of the new facility. By streamlining operations and ensuring timely delivery, John Deere can meet the evolving needs of its customers in the U.S. market. The Indiana distribution centre is expected to contribute significantly to the state's economic growth through approximately 150 jobs created. Overall, these investments demonstrate John Deere's commitment to supporting local economies and strengthening the backbone of American industry.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 30, 2026

Raimondi Cranes to Showcase Terex Lifting Brands at CONEXPO-CON/AGG 2026

Following its acquisition of Terex lifting brands, Raimondi Cranes will participate in CONEXPO-CON/AGG 2026 in Las Vegas, Nevada, from March 3 to 7. This marks the Group's first public exhibition since the acquisition, which includes Terex tower crane, self-erecting crane, and rough terrain crane businesses, along with a U.S.-based service infrastructure. The event will showcase Raimondi's commitment to delivering customer-driven solutions that meet operational and regulatory requirements while supporting rapid project timelines. Visitors will have the opportunity to learn about the latest developments within the tower cranes portfolio, including new flat-tops and luffing jib cranes engineered in response to increasing market demand for higher lifting capacities and enhanced operational efficiency models. The rough terrain crane range will be a key highlight of the Group's showcase, featuring exceptional lifting capacities with advanced mobility. Raimondi is now positioned to offer a stronger, more localized support network through its recent establishment of Raimondi North America, further reinforcing its intent to serve American customers with greater responsiveness and proximity. The event highlights Raimondi's long-term growth trajectory and underscores its ongoing commitment to the U.S. market expansion. With a delegation including senior managers from Raimondi and Terex Tower Cranes, Terex Rough Terrain Cranes, and the North American support team, the Group will showcase its latest developments and strategic direction in the outdoor exhibition area. The participation at CONEXPO marks a step forward for Raimondi, bringing a whole new dimension to its portfolio with the high-performing Terex Rough Terrain range.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 30, 2026

SBM's Large Impact Crusher Makes North American Debut at CONEXPO-CON/AGG

The tracked SBM REMAX 600 large impact crusher is set to make its North American trade show debut in Las Vegas, marking a significant milestone for the company. This flagship model of SBM Mobiles boasts an impressive range of features and capabilities that are sure to turn heads in the industry. With a maximum capacity of 600 tph and a feed size of up to 40 inches, the REMAX 600 is designed to be a powerful primary crusher or a mobile gravel or recycling plant capable of producing up to five end products in a single pass. Whether used for quarrying or recycling purposes, this 80-ton behemoth sets a new standard for its class. Its advanced features and capabilities make it an attractive option for those looking to upgrade their operations. The REMAX 600's hybrid electrified drive concept is particularly noteworthy, featuring an onboard Cummins X15 diesel engine paired with a 520 kVA generator and predominantly electric auxiliary drives. This innovative design not only reduces fuel consumption by up to 40 percent but also delivers significant benefits in terms of uptime and environmental performance. With its extensive range of standard equipment and optional add-ons, the REMAX 600 is well-equipped to meet the diverse needs of its users. From double deck circular vibrating screens to attachable production screens with up to three decks, this impact crusher has it all. The addition of two discharge magnets and air classifiers further enhances its capabilities, making it an ideal choice for producing high-quality recycled end products. With its quick-connect cabling and intelligent SBM CRUSH CONTROL system, the REMAX 600 is a machine that can be easily customized to suit any operation. Its one-piece transport design allows all equipment to remain on the machine during transport, making it a convenient option for those who need to move quickly. Whether used as a primary crusher or a mobile plant, the REMAX 600 is sure to make a lasting impression at CONEXPO-CON/AGG.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 30, 2026

Caterpillar to Deliver Power to Hyperscale AI Facility in West Virginia

American Intelligence & Power Corporation , Caterpillar Inc. , and Boyd CAT have entered into a strategic alliance and purchase agreement to support the development of AIP Corp's flagship site, the Monarch Compute Campus. This site is a large-scale, multi-phase power generation and infrastructure platform designed to deliver long-term, high-reliability power solutions to hyperscale and enterprise data centre customers. Under the purchase agreement, AIP Corp has ordered 2 GW of fast-response natural gas generator sets to support the initial phase of Monarch, with deliveries scheduled from September 2026 through August 2027. The fast-response generation equipment will be augmented with battery energy storage systems designed to handle the extreme load swings of AI data centers. The Caterpillar equipment and battery systems are expected to be commissioned and ready to deliver power within months of equipment delivery, supporting Monarch's accelerated time-to-market strategy to meet rapidly growing power demand from data centers. This 2-GW order supports Monarch's initial phases, with additional phased expansion planned over time. The Caterpillar G3516 fast-response natural gas generator sets are well-suited for behind-the-metre data centre applications due to rapid start capability, load-following performance, and high reliability in continuous-duty operation. The gensets will operate on natural gas and incorporate advanced emissions controls, including selective catalytic reduction (SCR), to support ultra-low emissions performance and compliance with all relevant air permitting requirements. Monarch will use advanced monitoring and control systems to support high availability, operational resilience, and predictable lifecycle performance. Designed as a fully self-supplied, behind-the-metre power platform, Monarch generates power onsite and does not require incremental utility transmission or distribution infrastructure to serve its load. With a target of 8 GW of planned generation capacity and an existing West Virginia microgrid designation, Monarch is designed to not increase rates or add costs for existing utility customers and will support long-term grid reliability and resilience. In parallel with the purchase agreement, AIP Corp and Caterpillar have entered into a strategic alliance agreement establishing a streamlined framework for collaboration focused on equipment optimization, phased expansion planning, operations and maintenance strategy, and long-term lifecycle performance, including service readiness and parts support planning. The alliance also includes vendor equipment financing through Caterpillar Financial, subject to customary terms and conditions, and aligned with equipment delivery phasing to support efficient project execution.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 29, 2026

John Deere's L-III Wheeled Feller Bunchers Simplify Logging Operations with Intuitive Features

The new L-III wheeled feller buncher models from John Deere are designed to make logging operations more efficient and comfortable for operators. With features similar to the L-III skidder models, these machines offer a range of precision solutions to deliver optimal machine and operator efficiency. The base and premium cab package options, premium lighting options, and enhanced connectivity capabilities are just a few examples of the intuitive features that set these machines apart. In addition, Remote Display Access (RDA) enables dealers, owners, and support personnel to view and interact with the machine's display from any location with an internet connection, saving time and increasing productivity. The L-III wheeled feller bunchers also feature a secondary display standard in all models, providing near real-time access to viewpoints outside of the machine. Furthermore, the advanced lighting systems come standard with LED lights, offering 200 percent increase in light output and enhanced visibility in low-light conditions. Premium lighting package options are also available for customers needing added high beam, grill, and service lighting. With these features, John Deere's L-III wheeled feller bunchers simplify tough work and help operators maximize uptime and efficiency.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 29, 2026

Felling Trailers Redesigns Drop Deck Series with Enhanced Structural Performance

Felling Trailers has recently released its new standard in trailers, the Drop Deck I (DDI) Series, formerly known as the I Series. This redesign enhances structural performance and expands capabilities for contractors, landscapers, and equipment operators in North America. The DDI design features a versatile diamond tread deck header plate that comes standard with integrated chain slots and pre-drilled mounting locations for accessories, making it customizable for various equipment being hauled. The trailer's modular, bolt-on ramp system uses interchangeable legs and hold-up pins, streamlining production and featuring clearly marked capacity ratings for safer job site load planning. Every enhancement in the DDI Series reinforces Felling Trailers' commitment to delivering quality trailers efficiently. Standardized components, fewer unique parts, versatile options, and optimized production workflows result in shorter lead times and consistent quality. The new press technology combined with an optimized hitch bend point significantly reduces deformation, delivering enhanced structural integrity, cleaner aesthetics, and a professional appearance. This redesign is a testament to Felling Trailers' investment in beam-bending equipment and their dedication to meeting the evolving needs of their customers.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 29, 2026

MDS to Showcase Flagship Screener at CONEXPO-CON/AGG

MDS will showcase its flagship M515 heavy-duty trommel at CONEXPO-CON/AGG 2026, marking a significant milestone in the brand's 30-year history. The M515 is widely recognized for its performance in processing tough materials and remains the centrepiece of the MDS portfolio. Its unique features, such as the drum design, large hopper capacity, and ability to handle rock up to 31.5 inches, make it particularly well suited for rip rap production. Operators consistently highlight the M515's ability to clean dirty shot rock, break down sticky material, and convert what would traditionally be waste into usable product. The machine's compact transport configuration offers a practical advantage for customers working across multiple sites. As the industry faces more complex material challenges and tighter operational demands, the M515 continues to stand out as a machine that simply gets the job done. With its strength, flexibility, and proven capability, it is a valuable asset for quarries across the region. MDS has strengthened its distributor relationships and expanded its support for contractors handling demanding material processing challenges. The brand's presence at CONEXPO-CON/AGG comes at a significant time, as it continues to grow its presence in North America. Starting Spring 2026, MDS will also have a dedicated regional sales manager based in the U.S., with Liam Óg Murray taking up the role. He brings practical on-the-ground experience that will strengthen support for MDS contractors and distributors across North America. The brand is proud to celebrate its 30-year anniversary and looks forward to connecting with operators, distributors, and customers at CONEXPO-CON/AGG.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 29, 2026

JLG Celebrates 50 Years of Scissor Lift Innovation with All-New Micro Design

JLG Industries, Inc. has expanded its lineup of micro-sized scissor lifts with the all-new JLG ES2632M model — a compact solution designed to help contractors work more efficiently in tight and demanding environments. The launch marks an important milestone for JLG as the company celebrates 50 years of manufacturing scissor lifts, a legacy rooted in innovation, safety, and productivity at height. Founded in 1969 by John L. Grove, JLG entered the access equipment market with the introduction of its first boom lift in 1970, helping to transform how work at height was performed. In 1976, JLG launched its first scissor lift — the engine-powered Sizzor 15S — a move that further solidified the company's presence in height-access equipment innovation and contributed to significant advances in job site safety and efficiency. The ES2632M joins JLG's growing family of micro-sized scissor lifts, which also includes the ES1330M, the ES1530M, and the ES1930M models. Designed to enhance efficiency on congested job sites, the ES2632M features QuikFold rails that fold down in seconds to pass through standard doorways, a zero-turning-radius design for precise manoeuvring, and a standard leak-containment system to help protect sensitive work surfaces. JLG-exclusive onboard technologies, including Progressive Elevated Drive, Variable Tilt, and ClearSky Smart Fleet, support increased uptime, enhanced control, and improved fleet management. Customers can configure the ES2632M with an optional integrated mid-rail deck, providing an additional 19.5 inches of platform height to further expand versatility across applications. The expanded line-up offers operators a compact footprint, ample manoeuvrability and performance in both indoor and outdoor applications. This new model delivers a 25-foot-6-inch indoor platform height, 600-pound platform capacity, and a narrow 32-inch machine width, enabling operators to access confined spaces without sacrificing productivity. Fifty years after introducing its first scissor lift, JLG continues to build on a legacy that began with a single idea: To make work at height safer and more productive. Today, that legacy is carried forward through advanced electrification, intelligent technology and customer-inspired design across JLG's access equipment portfolio.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 28, 2026

Steelwrist to Showcase Strong North American Momentum at CONEXPO-CON/AGG 2026

Steelwrist will feature its latest product innovations and live demonstrations at CONEXPO-CON/AGG 2026 in Las Vegas, March 3-7. The company's largest and most interactive presence to date will highlight the benefits of combining tiltrotators with fully automatic quick couplers for excavator efficiency. Steelwrist will showcase its third-generation XTR tiltrotators and the fully automatic SQ quick coupler technology, as well as compact excavators equipped with these solutions. Visitors can expect to see real-world job scenarios demonstrated by multiple excavators equipped with Steelwrist solutions. The interactive demo shows will highlight how combining tiltrotators with fully automatic quick couplers and a shared set of work tools can significantly increase excavator efficiency. Additionally, the show will feature an electric-powered compact excavator equipped with the smallest XTR2 tiltrotator, demonstrating that Steelwrist solutions are available for smaller machines on the job site. The Steelwrist team from across the Americas will also be present to meet customers, dealers, and OEM partners to discuss how Steelwrist products can help contractors transform their excavators into true tool carriers.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 28, 2026

Cedarapids Introduces Innovative Screening Diagnostics System at CONEXPO-CON/AGG

Cedarapids will be showcasing its latest innovations at the upcoming CONEXPO-CON/AGG event, including its all-new screening diagnostics system, TRAC. This system is designed specifically for crushing and screening environments and has been engineered from the ground up by Terex engineers in response to customer requests. The CRH5064 plant will also be on display, featuring a 60 inch x 20 foot Cedarapids Advantage Series Feeder that improves crusher loading and fines removal. Additionally, the plant is available with multiple axle configurations and a removable feed-hopper module for improved transport flexibility. Other features include feeder lift, a jib crane for blowbar changes, a self-cleaning magnet, under-crusher pan feeder, and expanded electrical and conveyor options. The CRH5064 plant reflects Cedarapids' focus on performance and serviceability, while TRAC meets a long-expressed need from distributors for a diagnostic tool designed specifically for screening equipment. With its unique features and capabilities, TRAC has the potential to expand across future vibrating platforms. By showcasing these innovations at CONEXPO-CON/AGG, Cedarapids is demonstrating its commitment to providing customers with practical solutions that meet their needs. The event provides an ideal platform for Cedarapids to connect with customers and showcase its latest products and technologies. As a leading manufacturer of crushing and screening equipment, Cedarapids is well-positioned to capitalize on the growing demand for innovative solutions in this industry. With TRAC and the CRH5064 plant, Cedarapids is poised to make a significant impact at CONEXPO-CON/AGG. The company's focus on performance, serviceability, and innovation is likely to resonate with customers looking for reliable and efficient crushing and screening solutions. By introducing these new products and technologies, Cedarapids is taking a proactive approach to meeting the evolving needs of its customers. As the industry continues to grow and evolve, companies like Cedarapids are well-positioned to lead the way with innovative solutions that meet the demands of this fast-paced market. The introduction of TRAC and the CRH5064 plant represents a significant step forward for Cedarapids in terms of its commitment to innovation and customer satisfaction. With these new products, Cedarapids is demonstrating its ability to stay ahead of the curve and provide customers with the best possible solutions for their crushing and screening needs.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 27, 2026

Ford partners with Carhartt on special-edition Super Duty truck

Ford has partnered with Carhartt to launch a new program that provides essential dealership technicians with durable uniforms designed to meet the rigorous demands of the modern service bay. The program, launched in late 2025, offers a range of workwear options for men and women, including shirts, pants, jackets, sweatshirts, and accessories. Dealerships have the flexibility to choose between two program options: a managed workwear program or a direct purchase option. Through the managed program, uniforms are professionally cleaned, inspected, and repaired or replaced as needed, ensuring technicians always have crisp, clean apparel ready for work. The partnership also includes new merchandise and a special-edition 2027 Super Duty Carhartt truck, coming later this year. Ford designers visited the Carhartt store in downtown Detroit last year to gain insights into the company's products and design inspiration for the vehicle. This collaboration explores the intersection of heritage workwear and automotive craftsmanship, uncovering shared values of durability, innovation, and local pride. The program aims to simplify how Ford dealerships ensure their technicians are Ready for the Workday. Cintas provides nationwide service and scale for the uniform delivery. Ford and Carhartt's partnership represents a commitment to providing customers with apparel that works as hard as they do. The new uniforms are designed to meet the needs of modern service bay technicians, who require durable and functional clothing. The program is an important step in enhancing the overall customer experience at Ford dealerships.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 27, 2026

FleetWatcher Introduces Integrated Cameras for Enhanced Fleet Tracking

FleetWatcher has recently expanded its capabilities with the integration of fully integrated cameras, designed to provide a comprehensive fleet tracking solution. Built on tested MiTAC commercial hardware, these cameras are engineered to withstand harsh conditions and offer internal or external power options. This allows users to seamlessly integrate safety and operational data into one platform, eliminating the need for extra systems. The versatility of the camera is further enhanced by its ability to tune event thresholds based on driver behavior, vehicle type, and environmental conditions. Dual-SIM LTE and backup power ensure that footage is never lost, providing a reliable insurance safeguard. With self-installation in just 30 minutes using adhesive mounts and plug-and-play connectors, FleetWatcher cameras offer an efficient solution for fleets of all sizes. Additionally, automatic firmware updates ensure the cameras remain optimized. By layering safety onto the existing FleetWatcher platform, this development provides a natural progression from their 25 years of operational experience with load cycle tracking, e-ticketing, ECM data, and monitoring KPIs. The integration of cameras into the system not only enhances fleet management but also provides real-time in-cab alerts to prevent issues such as fatigue, phone use, seat belts, speeding, following distance, cornering speed, and more, before they escalate. This flexibility is designed from the start, allowing different rules for different divisions or configurable alerts and adjustable sensitivity. Role-based dashboards further enable coaches to only see their drivers' data. The cameras also offer local storage and cloud backup, ensuring that pre- and post-event recordings are always available and protected from unauthorized access.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 27, 2026

FleetWatcher's Camera Feature Brings Total Visibility and Accountability to Your Fleet

FleetWatcher has introduced a camera feature built on tested MiTAC commercial hardware, providing tough and reliable cameras for fleet management. The cameras are designed with internal or external power options and can withstand harsh conditions. This allows users to track safety and operational data in one place, streamlining the collection of footage without requiring additional systems. The versatility of the camera enables users to set event thresholds for drivers, vehicles, and conditions, ensuring that only relevant footage is recorded. Dual-SIM LTE and backup power ensure that there is no lost footage, providing a dependable insurance safeguard. With self-installation in just 30 minutes using adhesive mounts and plug-and-play connectors, FleetWatcher cameras are an ideal solution for fleets of all types and sizes. The cameras also include automatic firmware updates to ensure they remain optimized. Additionally, the system provides all fleet and safety data on one economical platform, making it a natural progression from their existing load cycle tracking, e-ticketing, ECM data, and monitoring KPIs. All footage is encrypted, contractor-owned, and protected from third-party access. With local storage and cloud backup, pre/post-event recording is always available. The system also allows smart coaching with real-time in-cab alerts to prevent issues such as fatigue, phone use, seat belts, speeding, following distance, cornering speed, and more, before they escalate. Flexibility is designed into the camera from the start, allowing different rules for different divisions or configurable alerts and adjustable sensitivity. Role-based dashboards also mean that coaches can only see their drivers.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 27, 2026

JLG Industries Adds AUSA Wheeled Dumpers and Forklifts to North American Portfolio

JLG Industries, Inc. has expanded its product lineup in North America by adding the AUSA all-terrain compact equipment range, comprising 12 wheeled dumpers and five rough-terrain forklifts. The AUSA products are engineered to support durability, manoeuvrability, and performance across various applications, including construction, municipal, golf course, landscaping, agricultural, and civil material-handling projects. The JLG AUSA ED33 electric dumper is a 3,300-lb load capacity model designed for all-terrain performance with minimal noise emissions. The range spans multiple payload classes, supporting applications from municipal work to large-scale earthmoving projects. The machines feature permanent four-wheel drive and compact designs, providing excellent manoeuvrability on narrow terrain and steep slopes. Reversible dumper models further enhance operator visibility by allowing the cab to rotate 180 degrees, improving situational awareness. AUSA rough-terrain forklifts are available in a wide range of payload capacities, engineered for reliable performance in challenging environments. The machines deliver excellent off-road handling and efficiency, making them ideal for material handling needs in construction, agriculture, and municipal operations. With the addition of these products, JLG aims to support customers working on residential, municipal, golf course, civil, and road construction projects, as well as groundskeepers and trade professionals needing help with the transportation and handling of industrial and agricultural materials.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 27, 2026

Bobcat's Attachment and Implement Lineup Continues to Expand

Lift and unroll large round hay bales with ease using Bobcat's bale unroller. Designed for efficiency and precision, this implement connects to compact and utility tractors to streamline heavy bale handling. The Bobcat broadcast spreader is designed for fast, reliable material distribution across large areas, offering adjustable speed and gate controls for spreading salt, sand, seed or fertilizer. Its rust-resistant poly hopper and sealed electronics ensure durability, while custom wiring harnesses integrate with utility vehicles, compact tractors, and Toolcat utility work machines. This broadcast spreader is ideal for winter maintenance and all-season tasks. The Bobcat PC auger delivers exceptional versatility and torque for a wide range of digging applications, featuring an innovative combination of 2-inch hex and 2.5-inch round shaft on the 12PC and 25PC models. This design allows operators to use both 2-inch hex and 2.5-inch round output shafts with a single auger drive. As a result, operators have greater flexibility when selecting bits for different hole sizes and soil types. The auger offers high-speed, low-torque performance for softer soils. It also delivers higher-torque, lower-speed power for demanding conditions such as rock, clay, shale, and frost. Designed for use with multiple carriers, the PC auger is compatible with skid-steer loaders, compact track loaders, mini excavators and Toolcat machines. Together, these features set a new standard for versatility and productivity. The mini-pallet fork attachment is engineered for small loaders and mini track loaders, offering a compact solution for lifting and transporting materials. Its manually adjustable 36-inch forks meet ISO standards for strength and durability, making it ideal for landscaping, construction, and agricultural tasks. The brick guard design enhances visibility and safety, while compatibility with Bobcat's quick-attach system ensures easy installation. Bobcat's brush grapple attachment provides a powerful clamping force for handling brush, roots and debris. Its wide opening accommodates bulky materials, while below-grade capability helps remove stubborn vegetation. A simple single-cylinder design reduces maintenance, and protected hose routing improves reliability. Lightweight construction maximizes lift capacity, making it perfect for land clearing, trail maintenance, and farm cleanup. The Bobcat high-flow planer is engineered for milling asphalt and concrete with precision and efficiency, leveraging increased hydraulic horsepower for demanding applications. It features dual direct-drive motors for maximum torque, hydraulic side-shift for flush cuts along curbs, and free-floating oscillation to maintain consistent depth even on uneven surfaces. Fingertip in-cab controls allow operators to adjust depth and angle on the go, while integrated priority valves ensure uninterrupted cutting power during adjustments. Optional water kits provide dust suppression and bit lubrication, making this attachment ideal for roadwork, utility installation, and surface preparation tasks. The stump bucket is a heavy-duty, non-hydraulic attachment designed for aggressive digging, prying, and removal of tree stumps, roots, and large rocks. Its long, tapered profile, and serrated side plates slice through tough soil, making it ideal for land clearing, trenching, and site preparation. Equipped with weld-on Esco teeth for maximum penetration and durability, the bucket's reinforced structure ensures strength under extreme loads. Compatible with skid-steer and compact track loaders, it offers a cost-effective solution for demanding excavation tasks without the need for hydraulic components. The rotating log grapple is designed to deliver advanced precision and efficiency for forestry, landscaping and grounds maintenance applications. Featuring 360-degree continuous hydraulic rotation, it allows operators to reposition logs and brush without moving the loader, minimizing ground disturbance and improving productivity. Integrated features such as a tree pusher and rope bollards for controlled felling. Compatible with select mini track loaders and small articulated loaders, this attachment targets competitive markets by offering superior manoeuvrability and reduced operator fatigue. With these new attachments and implements, Bobcat continues to expand its lineup, providing customers with solutions that boost productivity and flex across countless applications. This expansion is a testament to the company's commitment to innovation and customer satisfaction. As the demand for versatile and reliable equipment grows, Bobcat is well-positioned to meet this need, offering a wide range of attachments and implements that cater to diverse industries and applications. By providing operators with more options and flexibility, Bobcat aims to empower them to take on more tasks with fewer machines, ultimately driving productivity and efficiency in the field. The company's focus on innovation and customer satisfaction is evident in its latest additions to the attachment lineup, which are designed to deliver exceptional performance and reliability. Whether it's for landscaping, construction, agriculture, or forestry, Bobcat's new attachments and implements are poised to make a significant impact in various industries. By expanding its product offerings, Bobcat aims to establish itself as a leader in the equipment market, providing customers with the tools they need to succeed. With its commitment to innovation and customer satisfaction, Bobcat is well-positioned for continued growth and success in the years to come.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 27, 2026

Bobcat Expands Attachment and Implement Lineup

Bobcat continues to evolve its attachment and implement lineup with the introduction of new products designed for efficiency and precision. The company's bale unroller, broadcast spreader, PC auger, mini-pallet fork attachment, brush grapple attachment, high-flow planer, stump bucket, rotating log grapple, and other attachments cater to various tasks such as heavy bale handling, material distribution, digging, landscaping, land clearing, asphalt milling, and forestry. These new additions enhance the versatility and productivity of Bobcat's compact and utility tractors, skid-steer loaders, compact track loaders, mini excavators, and Toolcat machines. With a focus on reliability and durability, these attachments are designed to meet the demands of operators who need solutions that can handle a wide range of applications with ease. Whether it's winter maintenance or all-season tasks, Bobcat's expanded attachment lineup offers a comprehensive solution for operators looking to boost productivity and efficiency. The company's goal is to empower operators to take on more tasks with fewer machines, making its products an ideal choice for those seeking to maximize their equipment's potential. By expanding its attachment lineup, Bobcat aims to further solidify its position as a leader in the industry.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 27, 2026

Advanced Performance on D11 Dozers with ESCO Mining Ripper System

Ripping with large dozers in mining, aggregate, or heavy construction applications is one of the most demanding conditions for ground engaging tools. ESCO's latest ripping innovation, the Nexsys Ripper System, delivers advanced performance on D11 dozers. The attachment was developed using finite element analysis and discrete element modelling to increase system strength and stability. This resulted in increased reliability, safer in-field replacement, and better performance than conventional ripper systems. The upgraded nose has higher strength and stability to withstand ripping at its toughest, while the optimized point profile assists with material flow and is configured for better penetration while maintaining sharpness throughout its service life. A sealed hammerless lock simplifies point replacement. Major system attributes include increased durability and reduced maintenance costs. This makes it an attractive option for mining, aggregate, and heavy construction applications. The Nexsys Ripper System has been extensively field tested to ensure optimal performance in demanding conditions. With its advanced technology and robust design, this attachment is poised to revolutionize the way large dozers rip through tough materials.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 23, 2026

Skyjack Unveils the SJ6940 RT: The Tallest Compact Scissor Lift for Harsh Ground Conditions

The latest addition to Skyjack's rough-terrain scissor lift lineup is the all-new SJ6940 RT, engineered with productivity and job site versatility in mind. With a working height of 46 feet (14.02 meters) and a platform capacity of 800 lbs (362.874 kg), this new machine sets a new benchmark as the tallest machine in Skyjack's compact RT scissor class. Designed to tackle tough job site terrain, the SJ6940 RT features an oscillating front steer axle and auto-leveling outriggers for maximum usability. The four-wheel driveline with wheel motors, torque hubs, and oscillating front axle provide superior traction, manoeuvrability, and a 35 percent gradeability rating ensuring excellent mobility across challenging terrain. With its impressive capacity and advanced features, the SJ6940 RT is an ideal solution for indoor and outdoor construction, maintenance, and industrial applications. Skyjack's renowned durability and commitment to sustainability make this machine a reliable choice for rental and building companies. The new SJ6940 RT offers outstanding performance and an 800 lb (362.874 kg) capacity to support more people, tools, and materials. With its HVO compatible engine and dual fuel option in North America, this machine is designed to outperform in rough terrain conditions and minimize environmental impact. By combining advanced technology with a focus on productivity, Skyjack has created a machine that is purpose-built to meet the needs of job sites across various industries.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 23, 2026

Caterpillar's Mini Excavator Features Elevated Hydraulic Horsepower in Compact Design

Caterpillar has recently introduced its mini excavator, featuring elevated hydraulic horsepower in a compact design. This new machine is designed to assist operators with controlling the excavator, improving accuracy and enhancing overall productivity. The Cat Indicate and E-Fence software packages are available from the factory or as a field upgrade kit, providing contractors with two options to suit their needs. The Indicate system provides visual and audible indicators to where the bucket is versus target grade, making it ideal for applications such as digging footings, septic systems, foundations, slope work, and similar projects. On the other hand, the E-Fence system automatically constrains machine motion within preset boundaries, allowing operators to work confidently and efficiently by avoiding structures. Additionally, the Laser Catcher technology provides a consistent reference point across the site, reducing the requirement for manual grade checking. The Cat Grade automatics offer contractors the ability to create, manage, and grade simple to complex designs with accuracy, ensuring cuts are filled to exact specifications. The new 308 CR Fixed Boom mini excavator builds on many of the next generation design features popular with the 307.5 model.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 22, 2026

DEWALT's Autonomous Downward Drilling Robots Revolutionize Data Centre Construction

DEWALT, a leading manufacturer for job site professionals, has partnered with August Robotics to develop an autonomous downward drilling robot designed to accelerate data centre construction. This fleet-capable robot enables fast, safe, and efficient concrete drilling, unlocking greater drilling capacity and driving cost-efficiency. The robot's impact on data centre construction is significant, having completed 10 phases of construction with a tech company, significantly boosting output and reducing construction timelines by 80 weeks across 10 projects. The robot has also delivered 99.97 percent accuracy for over 90,000 holes, radically decreasing the cost per hole. This addition strengthens DEWALT's data centre ecosystem, complementing their PERFORM AND PROTECT tools and technology that mitigate vibration and dust, as well as their industry-leading ICC anchoring solutions. The robot is poised to redefine how the world builds by accelerating construction speed, reducing costs, and enhancing jobsite safety. With hyperscalers investing heavily in infrastructure to power AI computing, this robotic drilling solution meets a critical need in the industry. As the demand for data centres continues to grow, innovative solutions like this are crucial for meeting global AI processing needs.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 22, 2026

Register Now for the 2026 National Heavy Equipment Show in Ontario

The 2026 National Heavy Equipment Show is coming to Ontario, and it's time to register for the event. The show will take place in February 2026, providing a unique opportunity for heavy equipment professionals to connect with industry leaders, learn about the latest technologies, and showcase their products. This year's event promises to be bigger and better than ever, with a wide range of exhibitors and attendees from across North America. The National Heavy Equipment Show is one of the largest events of its kind in Canada, attracting thousands of visitors each year. It's a must-attend event for anyone involved in the heavy equipment industry, from manufacturers and suppliers to rental companies and end-users. The show will feature a vast array of exhibits showcasing the latest heavy equipment, attachments, and services. Attendees will have the chance to see the latest innovations and advancements in the field, as well as network with fellow professionals and make new connections. The event will also include educational seminars and workshops, providing attendees with the opportunity to learn from industry experts and stay up-to-date on the latest trends and technologies. With its rich history and reputation for excellence, the National Heavy Equipment Show is an event not to be missed. By registering now, you'll be among the first to know about exhibitor lineups, special events, and other important updates. Don't miss your chance to be a part of this exciting event - register today! The show will take place at the Ontario Convention Centre in Toronto, Ontario, Canada. The event is open to professionals from across North America, including manufacturers, suppliers, rental companies, and end-users. Registration is now open for the 2026 National Heavy Equipment Show, so why wait? Sign up today and get ready to connect with fellow industry professionals, learn about the latest technologies, and showcase your products in front of a global audience.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 22, 2026

Atlas Copco's New Portable Air Compressor Offers Higher Flow and Fuel Savings

Atlas Copco has introduced its new portable air compressor, the X-Air 800-20, which combines higher flow with fuel savings. The compressor is powered by a highly efficient 6.7-litre Cummins engine, ensuring durability and performance in demanding environments. With AirXpert technology, the unit automatically regulates operating parameters based on real-time flow requirements, delivering 11 percent greater efficiency and reducing fuel consumption during drilling operations. This innovative approach helps contractors unlock maximum efficiency and control in every application. The X-Air 800-20 is designed to meet real-world needs by delivering higher flow at a practical pressure, which avoids unnecessary costs and complexity while improving efficiency and sustainability. By combining higher flow with practical pressure, Atlas Copco has created a solution that maximizes efficiency and accelerates productivity across diverse applications. The compressor's compact design simplifies transport and setup, allowing contractors to deploy high-performance air systems quickly and efficiently. Engineered for reliability, the X-Air 800-20 is built to withstand tough job site conditions while maintaining consistent performance. With its advanced computing power and enhanced monitoring capabilities, the Xc2004 controller helps contractors optimize their operations and achieve better results. The Dynamic Flow Boost feature further enhances performance by increasing flow during the most demanding phases of drilling, such as flushing and drill stem refilling. This addition ensures quicker borewell completion and streamlined operations. According to Srijayan Iyer, product marketing manager for Large Air, 'The X-Air⁺ 800-20 is all about giving customers more of what they need—and less of what they don't.' By combining higher flow with practical pressure, Atlas Copco has created a solution that maximizes efficiency and accelerates productivity across diverse applications. The X-Air 800-20 is an ideal choice for contractors who require high-performance air systems in demanding environments. With its advanced features and efficient design, this portable air compressor is poised to revolutionize the drilling industry.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 22, 2026

Cooper Equipment Rentals Names New CEO

After years of deliberate succession planning, Cooper Equipment Rentals has named Brian Spilak as its new Chief Executive Officer. The transition marks a significant milestone for the company, which has undergone significant growth and transformation under the leadership of current CEO Doug Dougherty. Since taking the helm in 2010, Dougherty has overseen a disciplined expansion strategy that has expanded the company's footprint from two locations to 89 nationwide. This period has also seen the completion of 18 strategic acquisitions, with revenue reaching over $500 million annually and a fleet valued at more than $1 billion. The company's growth is attributed to its focus on operational discipline and customer satisfaction. As part of this strategy, Cooper has built strong relationships with its customers and suppliers, ensuring a stable and supportive ecosystem for its operations. The leadership team has been instrumental in driving this success, and Brian Spilak is well-positioned to build upon this foundation. With his experience and expertise, Spilak is expected to continue executing the company's strategy and driving long-term growth. As Doug Dougherty transitions into an Executive Chair role, he will focus on board leadership, long-term strategy, and stewardship of Cooper's culture. The company's private equity partner, Seafort Capital, has expressed strong support for the transition, citing the strength of Cooper's organization and long-term strategy. With a solid foundation in place, Cooper Equipment Rentals is poised to continue its upward trajectory under Spilak's leadership.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 22, 2026

JLG's New Concept Offers Smarter Tracked Telehandler Solution for Tough Ground Conditions

JLG Industries, Inc. is set to unveil its innovative 1043T quad track telehandler solution at two major construction events in 2026. The new tracked lifting concept aims to provide contractors with improved mobility and productivity when working in challenging terrain. With a focus on tackling tough ground conditions such as loose or unstable soils, wet environments, and steep inclines, the 1043T Quad Track telehandler is designed to help operators stay on schedule despite difficult terrain. By combining the reach and capacity of a telehandler with the terrainability benefits of quad tracks, JLG's new concept model offers an alternative to traditional wheeled machines. The 1043T concept model features a rated capacity of 10,000-lb and a maximum lift height of 43-ft 5-in, making it suitable for below-grade foundation restoration, heavy civil construction, and deep sheeting and shoring projects. With its quad-track design, the 1043T Quad Track telehandler delivers better flotation than tires, reducing ground disturbance and enabling operators to work confidently on loose or unstable terrain. By previewing its new concept at World of Concrete in Las Vegas and CONEXPO-CON/AGG in Las Vegas, JLG is giving contractors a glimpse into the future of tracked mobility in construction. The 1043T Quad Track telehandler is designed to enable productivity in even the most challenging ground conditions, making it an attractive solution for contractors looking to stay ahead of the curve. As Daryl Stauffer, director product management, Telehandlers, JLG, notes, 'Contractors are being asked to do more work in tougher conditions, and that's exactly what inspired the innovation behind the 1043T Quad Track telehandler.' With its focus on delivering improved mobility and productivity, the 1043T Quad Track telehandler is poised to revolutionize the way contractors tackle tough ground conditions. By providing an alternative to traditional wheeled machines, JLG's new concept model offers a smarter tracked solution that can help contractors stay on schedule despite difficult terrain.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 22, 2026

Wacker Neuson Will Not Be Acquired by Doosan Bobcat

The acquisition of Wacker Neuson by Doosan Bobcat has been called off, leaving the future of the company uncertain. The decision was made after a thorough evaluation of the proposal. Wacker Neuson is a leading manufacturer of compact equipment, including mini excavators and wheel loaders. The company has a strong presence in Europe, with operations in over 80 countries. Doosan Bobcat is a major player in the construction industry, with a diverse product portfolio that includes excavators, wheel loaders, and material handlers. The proposed acquisition would have significantly expanded Doosan Bobcat's offerings in the compact equipment segment. However, after careful consideration, both parties have decided not to proceed with the deal. This decision may be a blow to Wacker Neuson's shareholders, who were likely expecting a significant increase in value as a result of the acquisition. The future of the company remains uncertain, and it is unclear what this means for its operations and employees. One thing is certain, however: Wacker Neuson will continue to operate independently, focusing on its core competencies and serving its customers with the same level of quality and expertise that has made it a trusted name in the industry. The decision not to pursue the acquisition may also have implications for Doosan Bobcat's strategy and priorities moving forward. While this deal is off the table, both companies will likely continue to explore opportunities for growth and expansion in the competitive compact equipment market.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 22, 2026

SMS Equipment Acquires Finnish Equipment Dealer to Expand European Presence

Canadian heavy equipment dealer SMS Equipment has announced the acquisition of Suomen Rakennuskone Oy, a Finnish distributor of construction and mining machinery. This deal marks an important milestone in SMS Equipment's international growth strategy, allowing the company to expand its global footprint and deepen its expertise in the mining and construction sectors. With operations in Alaska and Mongolia, as well as Finland, SMS Equipment is poised to become a leading player in the European market. The acquisition brings together decades of experience from SMS Equipment and Suomen Rakennuskone Oy's deep local knowledge, creating a powerful partnership that will drive growth and innovation in the Finnish construction industry. By combining their strengths, the companies aim to further develop Finland's robust mining sector, which is supported by significant reserves of cobalt and lithium, as well as nickel and gold production. The acquisition also underscores SMS Equipment's commitment to supporting its customers with a wide range of services, including sales, maintenance, parts, training, and technical support. With this expansion, SMS Equipment is well-positioned to capitalize on the growing demand for heavy equipment in Europe and beyond. As the company looks to the future, it will continue to build on its strengths and expertise, driving growth and success in the global mining and construction sectors. The acquisition of Suomen Rakennuskone Oy represents a significant step forward for SMS Equipment, solidifying its position as a leading player in the European market. By working together with Suomen Rakennuskone Oy, the companies will be able to deliver even greater value to their customers and drive growth in the Finnish construction industry.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 21, 2026

Mack Trucks Unveils New Instrument Cluster Featuring Co-Pilot on TerraPro Model

Mack Trucks has introduced a new instrument cluster for its TerraPro model, showcasing the innovative Mack Co-Pilot system. This debut took place at the World of Concrete 2026 event, held from January 20-22 at the Las Vegas Convention Center in Nevada. The new instrument cluster is designed to enhance the driver's experience by providing critical information in a clear and accessible format. With the integration of the Mack Co-Pilot system, operators can expect improved functionality and usability, which is essential for maximizing productivity in demanding work environments. Mack Co-Pilot is expected to offer features that streamline operations and enhance safety. By presenting vital data directly in the driver's line of sight, this system allows for quicker decision-making and better situational awareness. This is particularly important in the construction and heavy-duty sectors where the TerraPro model is commonly utilized. The unveiling at the World of Concrete event highlights Mack Trucks' commitment to innovation and responsiveness to industry needs. As construction demands evolve, the integration of advanced technology in vehicles like the TerraPro will likely play a significant role in meeting those challenges. Experts in the transport industry recognize the importance of such advancements. The introduction of the Mack Co-Pilot system could set a new standard for instrument clusters in heavy-duty trucks, emphasizing the need for manufacturers to prioritize driver-centric technologies. Overall, the new instrument cluster for the Mack TerraPro marks a significant step forward in enhancing vehicle performance and operator efficiency. As the industry continues to embrace technological advancements, Mack Trucks remains at the forefront, ensuring that its models meet the evolving needs of its customers.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 21, 2026

Keestrack to Showcase Crushing Solutions at CONEXPO-CON/AGG

CONEXPO-CON/AGG, recognized as one of the largest construction trade shows in North America, is set to take place from March 3-7, 2026, in Las Vegas, Nevada. This prominent event serves as a significant platform for industry leaders to present their latest innovations and technologies. Among the exhibitors, Keestrack will be showcasing its advanced crushing solutions, emphasizing its dedication to providing profitable and sustainable mobile processing options for the aggregates, recycling, and mining sectors. Keestrack's participation in CONEXPO-CON/AGG underscores the company’s commitment to addressing the evolving needs of these industries. The company plans to highlight its innovative K6 scalper, which is designed to enhance efficiency in material processing. This model is particularly noteworthy for its ability to handle a variety of materials, making it a versatile choice for operators in the field. The event will attract a diverse audience, including contractors, suppliers, and manufacturers, all eager to explore the latest advancements in construction technology. Keestrack’s focus on sustainability aligns with the growing industry trend towards eco-friendly practices, which is increasingly important to both customers and regulatory bodies. Experts in the transport and construction sectors recognize the importance of such trade shows in fostering innovation and collaboration. By showcasing cutting-edge solutions, Keestrack not only demonstrates its technological prowess but also its proactive approach to meeting the challenges faced by the aggregates, recycling, and mining industries. As the countdown to CONEXPO-CON/AGG begins, anticipation builds around the potential for new partnerships and advancements that can drive the industry forward. Keestrack's commitment to sustainable and efficient mobile processing solutions will likely resonate with attendees, further solidifying its position as a leader in the market.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 21, 2026

SharpGrade Expands Grader Blade Lineup and Introduces New Wireless Blade Control Module

SharpGrade has announced the expansion of its grader blade lineup with the introduction of two new blades, the G119 and GF110. The company's latest innovation is a wireless blade control module that aims to improve operator efficiency and performance. Following the success of its previous model, the G109, SharpGrade has designed the G119 for large-frame machines in the 75-100 horsepower range. This new blade features SharpGrade's highly popular hydraulic retracting front wheel assembly, allowing operators to raise and lower the wheel system without leaving the cab. The GF110, on the other hand, is designed specifically for budget-conscious operators, delivering exceptional performance at a more accessible price point. Both blades offer powerful grading capabilities for larger-scale jobs. The introduction of these new blades reflects SharpGrade's commitment to innovation and customer satisfaction. With its extensive range of grader blades, SharpGrade has established itself as a leading manufacturer in the industry. The company's focus on operator feedback and performance has enabled it to create products that meet the evolving needs of customers. By expanding its blade lineup, SharpGrade is poised to continue delivering high-quality solutions to operators worldwide. The new blades are designed to enhance grading precision and efficiency, while also reducing costs without compromising performance. With these additions, SharpGrade's product portfolio has become more comprehensive and competitive in the market. The company's decision to introduce a wireless blade control module further emphasizes its commitment to innovation and operator satisfaction. This technology aims to improve the overall operating experience for customers, making it easier to manage their blades and optimize their grading performance. By investing in research and development, SharpGrade has created products that are not only effective but also user-friendly and efficient. The company's dedication to customer satisfaction is evident in its attention to detail and commitment to delivering high-quality solutions. With the introduction of these new blades, SharpGrade is well-positioned to maintain its market leadership and continue to grow its customer base. The company's focus on innovation and performance has enabled it to establish itself as a trusted brand in the industry. By expanding its blade lineup and introducing a wireless blade control module, SharpGrade has demonstrated its commitment to meeting the evolving needs of customers. This strategic move is expected to enhance the overall grading experience for operators worldwide. With these additions, SharpGrade's product portfolio has become more comprehensive and competitive in the market. The company's decision to introduce a wireless blade control module further emphasizes its commitment to innovation and operator satisfaction. This technology aims to improve the overall operating experience for customers, making it easier to manage their blades and optimize their grading performance.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 20, 2026

HD Hyundai names Mike Ross as new COO

HD Construction Equipment Hyundai North America has announced the promotion of Michael Ross to the position of Chief Operating Officer (COO). In this new role, Ross will be responsible for overseeing the daily operations of the company, ensuring that all processes run smoothly and efficiently. His leadership will be vital as he collaborates closely with Stan Park, the president and CEO of Hyundai North America, to shape and implement the organization’s operational strategy. Michael Ross brings a wealth of experience to his new position, having been with the company for several years. His understanding of the construction equipment market and operational dynamics will be instrumental in driving Hyundai's growth and adapting to changing industry demands. The promotion reflects the company's commitment to strong leadership and operational excellence. As COO, Ross will focus on enhancing operational efficiency and fostering a culture of continuous improvement within the organization. This is particularly important in the competitive landscape of the construction equipment sector, where innovation and responsiveness to market trends are crucial for success. The appointment of Ross is seen as a strategic move for Hyundai North America, especially as the company seeks to strengthen its market position and expand its product offerings. The collaboration between Ross and Park is anticipated to yield positive outcomes for the company’s operational framework and overall performance. Industry experts note that effective leadership at the operational level can significantly influence a company's ability to adapt to market fluctuations and customer needs. With Ross at the helm of daily operations, Hyundai North America is poised to navigate the complexities of the construction equipment market more effectively.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 20, 2026

Mammoet Lifting Solutions Replace Essential Oil and Gas Infrastructure in Fort McMurray

In the oil and gas sector, timely equipment maintenance and facility shutdowns are critical for minimizing costs. Even saving a single day during these processes can lead to substantial financial benefits for companies operating in this space. To achieve efficient scheduling, it is paramount to have the right personnel, meticulous planning, and appropriate equipment ready to go. Mammoet, a leader in heavy lifting and transport solutions, has been instrumental in addressing these challenges in Fort McMurray. Their expertise in lifting solutions is particularly valuable in the context of replacing essential infrastructure within the oil and gas industry. By deploying advanced techniques and equipment, Mammoet aims to streamline operations and enhance productivity. The success of any maintenance project hinges on precise execution, and Mammoet's strategies are designed to optimize this process. Their commitment to safety and efficiency ensures that projects are not only completed on time but also adhere to the highest industry standards. This approach is vital in a sector where delays can lead to significant financial repercussions. Moreover, the integration of innovative lifting solutions allows for a more flexible response to the unique demands of each project. With a focus on reducing downtime, Mammoet's efforts in Fort McMurray exemplify how specialized lifting solutions can transform operational capabilities in the oil and gas sector. As the industry continues to evolve, the importance of effective planning and execution cannot be overstated. In conclusion, the role of companies like Mammoet in replacing critical infrastructure is a testament to the ongoing advancements in the oil and gas industry. Their ability to combine skilled personnel with cutting-edge equipment positions them as a key player in ensuring that maintenance and shutdowns are executed efficiently, ultimately benefiting the entire sector.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 20, 2026

EDGE Innovate to Debut High-Capacity Waste Shredder at CONEXPO-CON/AGG

EDGE Innovate is set to unveil its latest innovations in material processing at the upcoming CONEXPO-CON/AGG 2026, emphasizing its commitment to the 'Get Your EDGE' initiative. The company will exhibit its equipment designed to enhance productivity, reduce operating costs, and ensure long-term reliability. Located in the Silver Lot, EDGE Innovate will introduce the new VS750s high-capacity waste shredder, which promises to be a significant addition to their product lineup. Alongside the VS750s, EDGE will also present the SCREENPRO S16, which is now available for the North American market. The introduction of the VS750s high-capacity waste shredder is expected to attract attention for its innovative features and capabilities, catering to the growing demand for efficient waste processing solutions. As the industry continues to evolve, the focus on productivity and cost-effectiveness remains paramount, making this launch particularly timely. The VS750s is engineered to meet these demands, showcasing EDGE Innovate's dedication to advancing material processing technology.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 20, 2026

Milwaukee’s MX Fuel Equipment System Delivers Cordless Power to Demolition Hammers

Milwaukee has introduced the MX FUEL Equipment System, designed to revolutionize the way professionals power their job sites. This innovative system focuses on providing trade-specific solutions that address the common challenges associated with gas and corded equipment. By eliminating these frustrations, the MX FUEL system promotes cleaner, safer, and more efficient operations on various job sites. One of the standout features of the MX FUEL Equipment System is its compatibility with a single battery platform. This means that all MX FUEL solutions operate using either MX FUEL REDLITHIUM or REDLITHIUM FORGE batteries. As a result, crews can seamlessly integrate new equipment into their existing fleet without the need for multiple battery types. This compatibility not only enhances operational efficiency but also simplifies the logistics of battery management on site. The introduction of cordless power tools, such as demolition hammers, marks a significant shift in how construction professionals approach their work. By leveraging battery technology, Milwaukee aims to reduce the dependency on traditional gas-powered tools, which often come with environmental and safety concerns. The move towards cordless solutions aligns with industry trends emphasizing sustainability and worker safety. As the construction landscape continues to evolve, the MX FUEL Equipment System positions Milwaukee as a leader in innovative power solutions. The ability to operate multiple tools on a single battery platform is particularly advantageous for contractors looking to streamline their operations and reduce downtime. This system not only enhances productivity but also contributes to a safer working environment by minimizing the hazards associated with gas and corded equipment. In conclusion, Milwaukee's MX FUEL Equipment System is set to change the dynamics of job site operations by providing a versatile, efficient, and safe alternative to traditional power tools. As more professionals adopt these cordless solutions, the construction industry may see a significant transformation in how work is conducted, with an emphasis on efficiency and environmental responsibility.

Heavy Equipment Guide (All news)·Heavy Equipment·Jan 20, 2026

Hydrogen-Powered Job Site Completes Successful Test with Liebherr Wheel Loader